When building robots, flexibility and movement are absolutely vital. Simple or circular mobility of traditional wheels hinders a robot’s capacity to negotiate confined areas or complex surroundings. Here mecanum wheels vs omni wheels are useful. These sophisticated wheel systems enable multidirectional mobility, thereby improving the agility of a robot and rendering them perfect for particular application situations such autonomous navigation, warehouse robots, and more.

Which wheel, though, should you use? Let us examine every kind in great detail.

What are Mecanum Wheels?

Design of Mecanum Wheels

Made of a sequence of rollers positioned at a 45-degree angle around the wheel’s edge, Mecanum wheels These rollers are positioned such that, depending on wheel rotation, the wheel may move in several directions. Usually complicated, the design calls for careful roller arrangement to obtain the intended movement.

How Mecanum Wheels Work

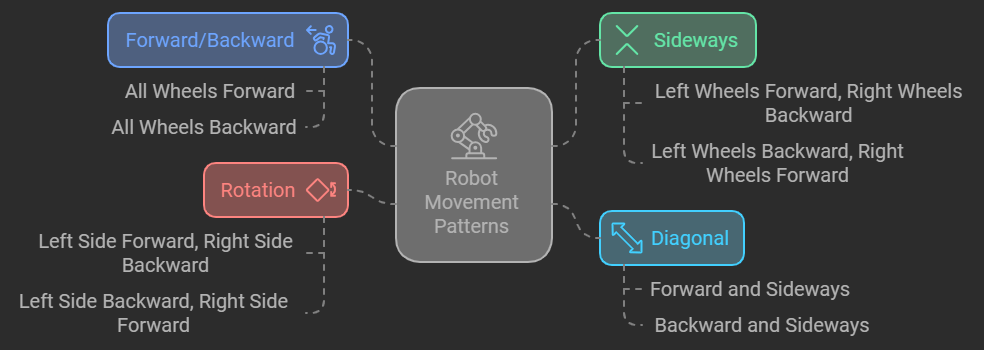

Mecanum wheels combine rotating action with the special 45-degree-angled rollers. A robot can accomplish various movement patterns by varying the direction and speed of rotation for every wheel. As one example:

- Forward or backward motion is achieved when all wheels rotate in the same direction.

- Sideways motion is achieved when wheels on opposite sides rotate in opposite directions.

- Diagonal motion is achieved by combining both forward and sideways movements.

- Rotation on the spot can occur by spinning wheels in opposing directions on either side of the robot.

This makes Mecanum wheels highly versatile for navigating tight spaces and complicated environments.

What are Omni Wheels?

Design of Omni Wheels

Omni wheels are designed differently than Mecanum wheels. Omni wheels include several rollers perpendicular to the axis of rotation instead of inclined rollers. These rollers let one move sideways without spinning the wheel itself. Though their shape is usually simpler than Mecanum wheels, Omni wheels feature multidirectional capability.

How Omni Wheels Work

Omni wheels operate via use of the wheel’s circumference’s rollers. Every roller lets the robot slide in several directions since each one moves freely. Like Mecanum wheels, Omni wheels enable:

- Forward and backward movement by rotating all wheels in the same direction.

- Side-to-side movement without rotating the main wheel, just by using the rollers.

- Rotation on the spot by altering the direction of individual wheels.

However, Omni wheels may not be as precise in diagonal movement compared to Mecanum wheels, due to the perpendicular nature of their rollers.

Mecanum Wheels vs Omni Wheels: Key Differences

Movement Patterns

Especially in diagonical orientations, Mecanum wheels provide more intricate and variable movement patterns. Conversely, Omni wheels offer smooth lateral movement; but, diagonal maneuvers call for more coordination.

Design and Construction

Because of its angled rollers, which provide Mecanum wheels considerably more complexity in design, Omni wheels have a simpler construction with perpendicular rollers. Omni wheels are therefore simpler to maintain, although Mecanum wheels could provide more strong performance in challenging conditions.

Applications

Mecanum wheels vs omni wheels find application in settings requiring more complex movement capabilities, such warehouse automation or robotics contests. Simple robots where minimum complexity and easy of movement are needed usually include Omni wheels.

Advantages of Mecanum Wheels

- Highly Versatile Movement: Mecanum wheels excel in environments where robots need to navigate tight spaces or perform complex maneuvers.

- Diagonal and Rotational Precision: The 45-degree rollers allow for accurate diagonal movement and in-place rotation, making it ideal for precision tasks.

- Enhanced Load Carrying: Mecanum wheels can handle heavier loads due to their more robust design.

Advantages of Omni Wheels

- Simpler Design: The straightforward design of Omni wheels makes them easier to implement and maintain.

- Smooth Lateral Movement: Omni wheels are great for situations that require smooth, sideways movement without much complexity.

- Cost-Effective: Omni wheels tend to be cheaper and more accessible for smaller projects.

Limitations of Mecanum Wheels

- Complex Design: The 45-degree rollers require more precision during construction and maintenance.

- Power Consumption: Mecanum wheels can consume more power due to the additional friction between the rollers and the ground.

- Higher Cost: The complexity of Mecanum wheels makes them more expensive than Omni wheels.

Limitations of Omni Wheels

- Limited Diagonal Movement: Omni wheels struggle with diagonal movement, which can limit their flexibility in certain situations.

- Less Load Capacity: Omni wheels may not handle heavy loads as efficiently as Mecanum wheels.

- Less Precision in Rotation: While they can rotate, Omni wheels may not offer the same rotational precision as Mecanum wheels.

Choosing the Right Wheel for Your Project

The particular needs of your project will mostly determine which of Mecanum wheels or Omni wheels you need. Mecanum wheels are perhaps the preferable option if you need sophisticated movement in several directions and are handling heavy weights. Omni wheels might be the better choice, though, if your project stresses simplicity, smooth lateral movement, and economy of expense.

Which Wheel is Better for Heavy Loads?

Mecanum wheels tend to perform better under heavy loads due to their more robust design and stronger grip.

Which Wheel is Better for Precision Maneuvering?

For tasks that require high precision in diagonal movement or tight rotational control, Mecanum wheels have the advantage.

Which Wheel is Better for Speed and Efficiency?

Omni wheels may offer better efficiency in terms of speed and power consumption, making them a good option for lightweight robots or tasks where energy conservation is crucial.

Common Use Cases for Mecanum Wheels

- Warehouse Robots: Mecanum wheels are used in automated robots that need to navigate tight aisles while carrying heavy loads.

- Robotics Competitions: The flexibility of Mecanum wheels makes them popular in competition robots that need to perform complex maneuvers.

- Service Robots: Robots that assist in healthcare or hospitality often use Mecanum wheels for their ability to move smoothly in any direction.

Common Use Cases for Omni Wheels

- Lightweight Robots: Omni wheels are commonly used in small robots where ease of movement and low power consumption are key.

- Office Automation: Robots that need to move around offices or other smooth-surfaced environments often use Omni wheels.

- Educational Robots: Due to their simplicity and cost-effectiveness, Omni wheels are often found in educational kits for beginner roboticists.

Conclusion

In the realm of robotics, both Mecanum and Omni wheels find application. Particularly for difficult or heavy-duty jobs, Mecanum wheels provide more adaptability and accuracy. Conversely, Omni wheels are more reasonably priced and offer better mobility in simpler uses. Your decision should be based on the needs of your project including load capacity, mobility, and financial constraints.

FAQs

- Are Mecanum wheels more expensive than Omni wheels?

Yes, Mecanum wheels tend to be more expensive due to their complex design. - Can Omni wheels move diagonally?

While Omni wheels can move sideways easily, diagonal movement requires more coordination and may not be as smooth as with Mecanum wheels. - Do Mecanum wheels consume more power?

Yes, Mecanum wheels generally consume more power due to the additional friction from the angled rollers. - Which wheels are better for robotics competitions?

Mecanum wheels are often favored in robotics competitions due to their flexibility and precision in movement. - Are Omni wheels suitable for heavy loads?

No, Omni wheels are better suited for lighter loads, while Mecanum wheels can handle heavier weights.